The Revolutionary Impact of Robotics on Modern Manufacturing

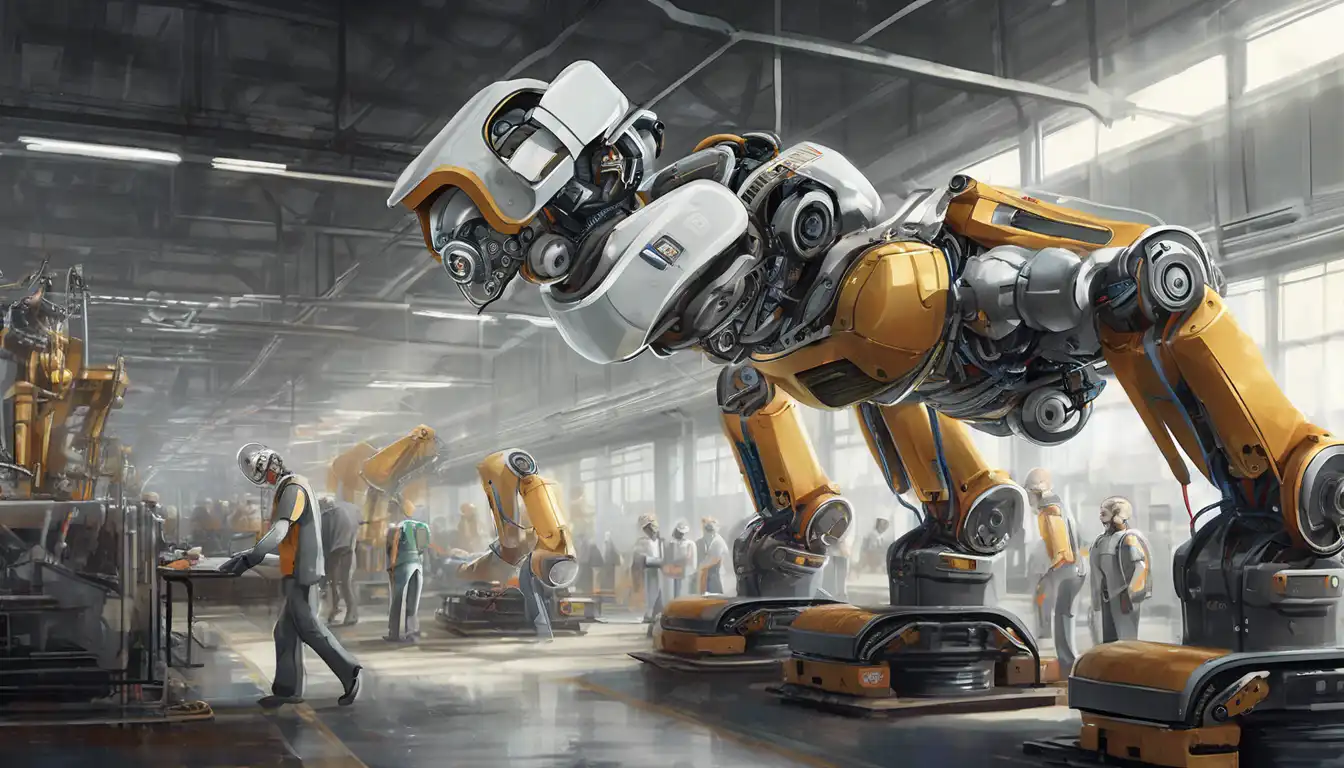

In the heart of the industrial revolution, the introduction of robotics into manufacturing processes has marked a pivotal shift towards efficiency, precision, and scalability. This transformation is not just about replacing human labor but enhancing capabilities, reducing errors, and opening new avenues for innovation.

Enhanced Efficiency and Productivity

Robotics in manufacturing has significantly boosted productivity by automating repetitive tasks, allowing for 24/7 production cycles without fatigue. This leap in efficiency is not only about speed but also about the consistency and quality of output, which manual processes struggle to match.

Precision and Quality Control

The precision of robotic arms and automated systems has elevated the standards of quality control in manufacturing. With advanced sensors and AI, these systems can detect and correct minute discrepancies in real-time, ensuring every product meets stringent quality criteria.

Cost Reduction and Scalability

While the initial investment in robotics can be substantial, the long-term savings are undeniable. Reduced labor costs, minimized waste, and lower error rates contribute to a significant decrease in operational expenses. Moreover, robotics offers unparalleled scalability, enabling manufacturers to easily adjust production levels in response to market demands.

Innovation and Future Prospects

The integration of robotics with emerging technologies like the Internet of Things (IoT) and artificial intelligence (AI) is paving the way for smart factories. These facilities are not only more efficient but also more adaptable and responsive to changes in production needs.

For those interested in the intersection of technology and manufacturing, exploring how AI is further transforming manufacturing can provide additional insights into the future of industrial production.

Challenges and Considerations

Despite the benefits, the transition to robotic manufacturing is not without challenges. The need for skilled personnel to operate and maintain these systems, along with concerns about job displacement, are significant considerations. However, the potential for robotics to create new roles and industries cannot be overlooked.

As we look to the future, the role of robotics in manufacturing is set to grow, driven by continuous advancements in technology and an increasing emphasis on sustainability and efficiency. The journey of robotics from simple automated machines to complex, intelligent systems mirrors the evolution of manufacturing itself, promising a future where the possibilities are limitless.

For more on the latest trends in manufacturing technology, check out our technology section for in-depth articles and analysis.